Manufacturers everywhere are rethinking how they operate, improve efficiency, and respond to changing market expectations. Improving operations in the production line is no longer a matter of adjusting guidelines and the engineering flow of the production line. It becomes a transformation of how deep learning algorithms and automation systems are integrated to change the operations of the production lines entirely. Every company in the field is looking to optimize its production systems to improve its connection and automation, and its ability to adapt to customer demands. The production systems need to be flexible and resilient to remain competitive.

In the blog, we are going to analyze what digital transformation in the manufacturing sector is, what challenges companies face, the role of the company in adopting the right technology, and what common problems companies are going to face. Then we are going to analyze the challenges and the tech transformation. We are going to analyze the sector in order to understand the challenges. Additionally, we are going to analyze the systems of connection, flexibility, and automation in order to optimize the services of the customer.

What Is Digital Transformation in Manufacturing?

Rather than merely a transforming process, it seeks to understand how data, automation, and enterprise digital transformation strategies can diversify the redesign of workflows and improve the efficiency of operations. It involves the use of digital transformation technologies, including automation, cloud computing, AI, and IoT tools. When deployed collectively, these innovations allow businesses to construct novel competencies, optimize the use of production facilities, improve the prediction of equipment failures, and enhance overall productivity.

A digital transformation consultant can help many businesses design and develop a strategy to achieve their objectives. This enables them to transition from their legacy processes to a more intelligent and interconnected framework for managing their factories. Digital transformation is, therefore, the link between traditional manufacturing and operations of the future.

What are the Core Technologies Powering Manufacturing’s Digital Shift

Several modern technologies work together to support corporate digital transformation in the manufacturing sector. Some of the most impactful ones include:

-

IoT and Smart Sensors

IoT sensors obtain and store information autonomously in real-time about machinery, assembly lines, and finished goods. Digital transformation with IoT allows teams to assess equipment condition and quality and to make guided decisions. With the help of IoT and digital technologies, factories are able to predict failures and avoid any interruptions in the production flow.

-

Artificial Intelligence and Machine Learning

AI provides the tools for better decision-making. Machine Learning can look at large data sets and recognize patterns. This enhances decision-making by reducing errors and improving flow efficiency in the production cycle. Routine work is also sometimes automated with AI, allowing for more strategic digital transformation by employees.

-

Cloud Computing

Cloud platforms are the digital transformation enabler in businesses by serving as a digital data hub. Manufacturers are then able to store, manage, and access data from different locations in a streamlined, controlled, and secure way. All cloud systems provide flexibility, meaning businesses can grow, and the cloud systems will grow with them.

-

Robotics and Automation

More work can be done at a faster rate. This is productivity and profitability. With modern-day automation, robots can also do more to improve accuracy and keep employees safer. This is one of the digital transformation focuses in enterprises, giving a positive impact on the business with no increase in workload.

-

ServiceNow for Manufacturing Sector

Many companies also use platforms like ServiceNow for the manufacturing sector to manage workflows, streamline maintenance processes, and automate service operations. This supports overall efficiency by connecting teams and improving communication.

-

Application Modernization

Older manufacturing systems often limit growth. Application modernization helps companies upgrade or replace legacy systems to create a more flexible and responsive digital architecture.

How to Implement Digital Transformation: Step-by-Step Framework

A structured approach helps manufacturing companies transition smoothly. Here is a simple step-by-step framework that many organizations follow during their company’s digital transformation journey.

Step 1: Assess Current Capabilities

Before embracing new technologies, manufacturers need to understand their current position. This entails reviewing processes, determining existing processes, and operational issues.

Step 2: Define Transformation Goals

Without goals, it will be impossible to make plans. Priorities can be improving efficiency and reducing downtime, and faster decision-making will help structure the digital transformation.

Step 3: Engage Stakeholders

The purpose behind the transformation should be communicated to leadership, IT, production teams, and frontline workers. This widespread understanding will make adoption easier.

Step 4: Choose the Right Technologies

Once goals are in place, companies are capable of pinpointing the technologies that are able to help achieve the objectives. This can be IoT, automation, cloud service, and other modern workflow applications.

Step 5: Modernize Applications and Systems

Outdated technologies encumber transformation. Having to convince yourself to keep the old systems will make it harder to modernize.

Step 6: Integrate Data Across Systems

Having a digital strategy in place will rely heavily on data. A digital strategy will integrate data across siloed systems, allowing companies to see a single coherent view of their operations.

Step 7: Pilot and Scale

Testing new digital transformation services on a smaller scale allows companies to refine their approach. Once the pilot succeeds, the solution can be expanded across all facilities.

Step 8: Continuous Improvement

Digital transformation is not a one-time project. Manufacturers must track results, collect feedback, and make continuous improvements to stay competitive.

Ready to modernize your manufacturing workflows with scalable digital transformation solutions in manufacturing?

Why Should Manufacturers Implement Digital Transformation?

Manufacturers are facing their toughest competition yet, and customers have higher expectations than ever before regarding delivery speed, customization, and quality. To keep up, companies need digital transformation strategies to enhance collaboration, transparency, and reduce operational downtime. One of the strongest motivators is the requirement for increased operational visibility. Outdated reporting methods slow down the decision-making process, while reporting systems are digitized for instant access and flag potential bottlenecks. This visibility enables better decision-making and a more efficient and seamless workflow across more collaboratively aligned teams.

There are also cost savings and operational efficiencies driven by process innovations associated with digital transformation. Predictive maintenance technology reduces unplanned downtime due to increased equipment failures and process automation to reduce manual errors and improve overall consistency. Manufacturers also improve demand forecasting to reduce overall waste and manage inventory more efficiently. The introduction of robotics, the IoT, and AI can also improve the overall digital transformation and innovation of a process by expanding the possible outcomes to a more valuable end for the customer. Digital transformation services improve process innovation to comply with operational requirements for reporting to improve traceability across the entire production cycle.

Challenges in Implementing Digital Transformation in Manufacturing

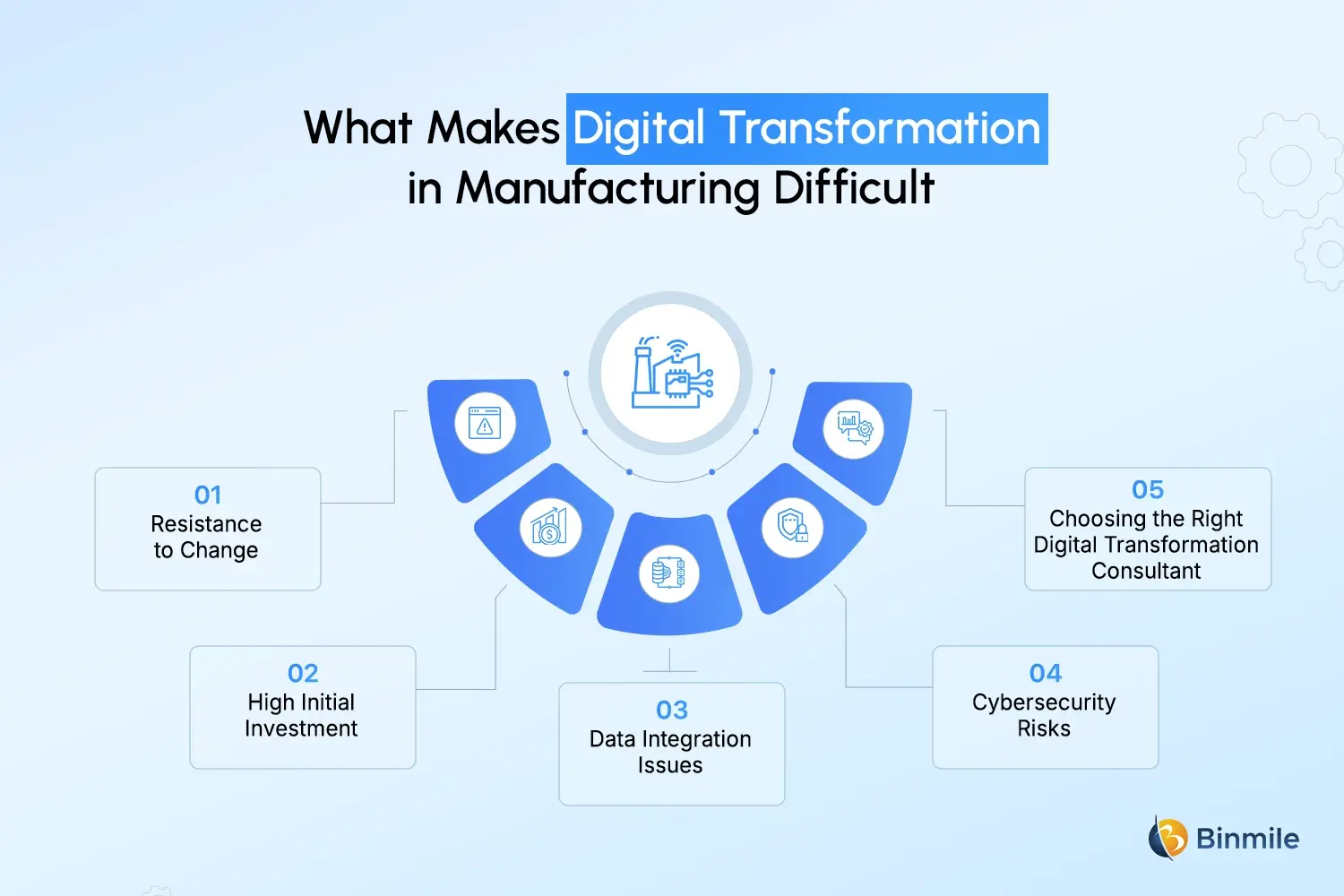

Manufacturers often encounter various digital transformation challenges as they move toward modernizing their operations. Some of the most common hurdles include:

-

Resistance to Change

Since many teams cooperate with standard procedures, adapting to automated or data-driven systems becomes burdensome. Tailored leadership and sensitization campaigns are necessary for effortless change.

-

High Initial Investment

While technologies like IoT, automation, and AI are inherently beneficial, the high cost associated with them cannot be ignored. Manufacturers require careful cost planning to capture the desired ROI sustainably.

-

Data Integration Issues

Most factories run on an array of systems that rarely interface with each other. This creates barriers to cultivating unified, real-time operational visibility and advances sluggishness in decision-making.

-

Cybersecurity Risks

With increased interconnectedness in factories comes the risk of exposure to cyber threats. Companies need to implement the most advanced security to safeguard sensitive data and operational resilience.

-

Choosing the Right Digital Transformation Consultant

Most transformation malfunctions result from misguided direction. Picking a consultant with an appropriate and practical understanding of manufacturing processes and vision is vital to outlining and sustaining a productive framework.

Looking to streamline operations and adopt the right technologies for the digital transformation in manufacturing?

How Binmile Strengthens the Digital Transformation in Manufacturing

For many manufacturers, navigating digital transformation can feel overwhelming because it involves much more than adopting modern tools. It requires a clear strategy, a detailed understanding of existing processes, and the ability to align technology with long-term digital transformation in business goals. This is where a reliable partner like Binmile becomes valuable in guiding the transformation with clarity and structure.

Their expertise in digital transformation solutions helps manufacturers evaluate their current systems, identify gaps, and build a roadmap that fits their operational needs. Instead of pushing generic solutions, their approach focuses on understanding how each factory operates and what improvements will create the highest impact. This includes everything from integrating IoT systems and automating workflows to modernizing legacy applications that may be slowing production.

Binmile also assists companies during the implementation process, which in most cases is the most challenging in the journey. Their expertise in the fields of application modernization and technology integration ensures that systems can be merged with ease and without disruptions on the shop floor. This ensures that the manufacturers move towards smarter and connected systems.

Another key strength is their focus on scalability. Digital transformation is not a one-time project, and manufacturing needs continue to evolve. By building flexible architectures and data-driven systems, they help companies stay prepared for future expansion, technology upgrades, and new market demands. With a strong understanding of industry requirements, Binmile helps manufacturers create a sustainable digital foundation that boosts efficiency, strengthens decision-making, and supports long-term growth.

Frequently Asked Questions

Real-time data and insights foster a more efficient and interconnected manufacturing ecosystem, improving efficiency and decision-making while reducing downtime and enhancing product quality.

Modernize old technology, establish clear objectives, align the right tech and digital transformation tools, motivate and involve employees, and encourage active participation from supportive leadership.

Common factors include budget restrictions, legacy systems, employee readiness, data silos, and inadequate scheduling.

The digital transformation of manufacturing leads to reduced costs through lower manual mistake rates, efficient resource planning, the elimination of downtime through predictive maintenance, and refined production flow.

The improvement in ROI more closely depends on the digital transformation. Most companies, with digital transformation, experience improvements such as efficiency gains, increased output, decreased operational costs, and faster decisions in the initial years.

Digitalization is as simple as applying IoT-connected sensors for machine performance monitoring. This includes creating a digital twin of a machine, which allows real-time monitoring, providing predictive maintenance to prevent breakdowns, etc.